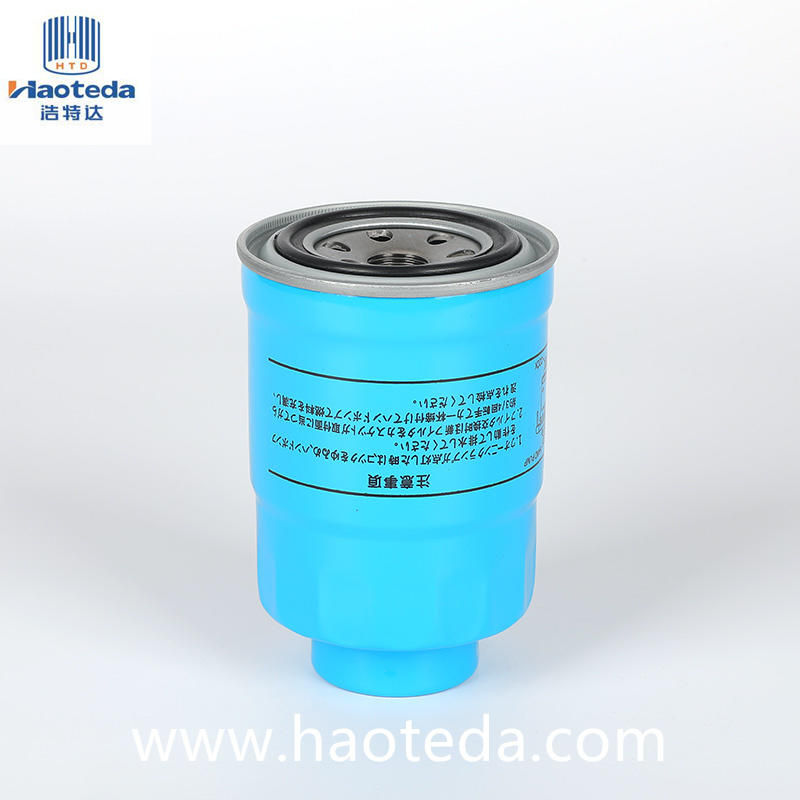

How does Fuel Filter filter different types of engine pollutants?

A

fuel filter is designed to filter out various types of pollutants and contaminants that can be present in the fuel. It utilizes the filter media and the structure of the filter to capture and separate different types of pollutants.

Particulate Contaminants (Dirt, Rust, Debris):

Particulate contaminants are solid particles that can enter the fuel system through the fuel tank, storage, or transportation. The filter media inside the fuel filter is designed to have microscopic pores that are smaller than these particles. As the fuel flows through the fil ter, these Larger particles are unable to pass through the pores and get trapped in the filter media. Over time, this buildup of particulate matter can clog the filter, necessitating replacement.

Water:

Water can enter the fuel system due to condensation in the fuel tank or from contaminated fuel sources. Many fuel filters incorporate a water separation feature to address this issue. Water is denser than fuel, so the filter design may include a water-absorbing media or a collection chamber at the bottom of the filter housing. Water droplets combine and settle at the bottom, away from the fuel outlet, allowing only clean fuel to pass through.

Microscopic Particles:

While the primary purpose of a fuel filter is to capture larger contaminants, the filter media's structure can also trap smaller particles. The density and construction of the media determine its ability to capture finer particles, such as tiny bits of debris or con taminants.

Rust and Corrosion:

If the fuel tank or fuel lines contain rust or corrosion, these particles can be carried into the fuel system. The filter media's fibers can catch these particles as they flow through, preventing them from reaching sensitive engine components.

Microbial Growth (Bacteria, Algae):

In certain conditions, microbial growth can occur in fuel tanks due to the presence of water and organic matter. Some

fuel filters have additives or media that discourage microbial growth, but the primary way to deal with this issue is to ensure water separation and mois ture control within the fuel system.

Why can Fuel Filter improve fuel system efficiency?

A

fuel filter plays a significant role in improving fuel system efficiency by ensuring that the fuel entering the engine is clean and free from pollutants.

Optimal Combustion:

Clean fuel is essential for proper combustion in the engine's cylinders. When the fuel is contaminated with particles, dirt, or water, it can disrupt the proper mixture of fuel and air, leading to incomplete combustion. Incomplete combustion can result in reduced power output, decreased fuel efficiency, and increased emissions. By filtering out pollutants, a fuel filter ensures that the fuel-air mixture is consistent and allows for more efficient and complete combustion.

Preserving Fuel Injectors:

Fuel injectors are responsible for precisely spraying fuel into the combustion chamber. Contaminated fuel can clog the tiny openings in fuel injectors, affecting the spray pattern and fuel atomization. This can lead to uneven fuel distribution, misfires, and reduced engine performance. A

fuel filter prevents pollutants from reaching the injectors, helping them maintain proper functionality and ensuring consistent fuel delivery.

Preventing Fuel Pump Wear:

In modern vehicles with electric fuel pumps located inside the fuel tank, debris and pollutants can damage the pump's sensitive components. A fuel filter acts as a barrier between the fuel pump and potential pollutants, reducing the wear and tear on the pump and extending its lifespan A healthy fuel pump is essential for maintaining consistent fuel pressure, which in turn contributes to efficient engine operation.

Reduced Maintenance Costs:

By preventing pollutants from reaching critical engine components, a fuel filter reduces the likelihood of costly repairs. Fuel injectors, fuel pumps, and other components can be expensive to replace. Regularly replacing the fuel filter is a relatively inexpensive preventive maintenance measure that can help avoid more significant expenses down the line.

Enhanced Fuel Economy:

When the engine receives clean fuel, it operates more efficiently. Clean fuel allows for better combustion, reducing energy waste and ensuring that the engine operates closer to its design parameters. As a result, a well-maintained fuel system can contribute to im proved fuel economy , helping you get more miles out of each gallon of fuel.

Minimized Emissions:

Efficient combustion achieved through clean fuel reduces the production of unburned hydrocarbons and other pollutants. This leads to lower emissions, which is not only environmentally beneficial but also ensures compliance with emissions regulations.

In essence, a fuel filter ensures that the fuel system components work optimally and that the engine receives clean fuel, leading to improved combustion efficiency, reduced wear on critical components, enhanced fuel economy, and minimized emissions. Regularly replacing the fuel filter as part of Routine maintenance is essential for maintaining these benefits and ensuring the long-term health of the fuel system and the engine.

English

English

English

English Español

Español Français

Français

+86-139-6774-0263

+86-139-6774-0263

.jpg?imageView2/2/format/jp2)