When it comes to maintaining your engine’s performance, the importance of a properly installed oil filter cannot be overstated. A Metal Oil Filter is designed to ensure that your engine receives the cleanest possible oil, free from harmful contaminants that could cause wear and tear. However, even the most high-quality filter won’t function as it should if it’s not installed correctly. This article explores why the proper installation of a Metal Oil Filter is critical for engine health and longevity and provides insights on how to avoid common mistakes that can compromise its performance.

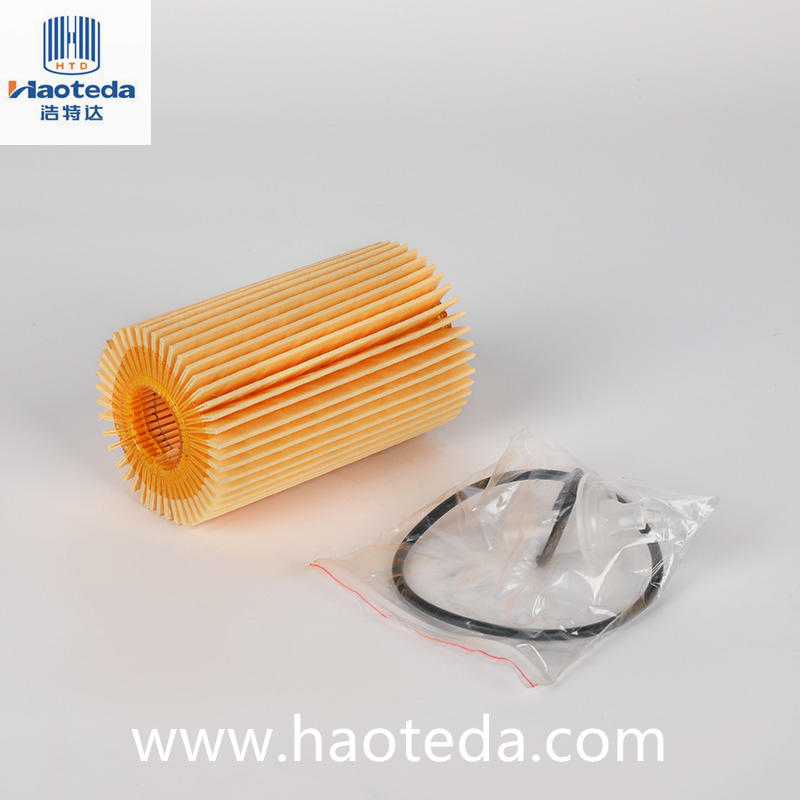

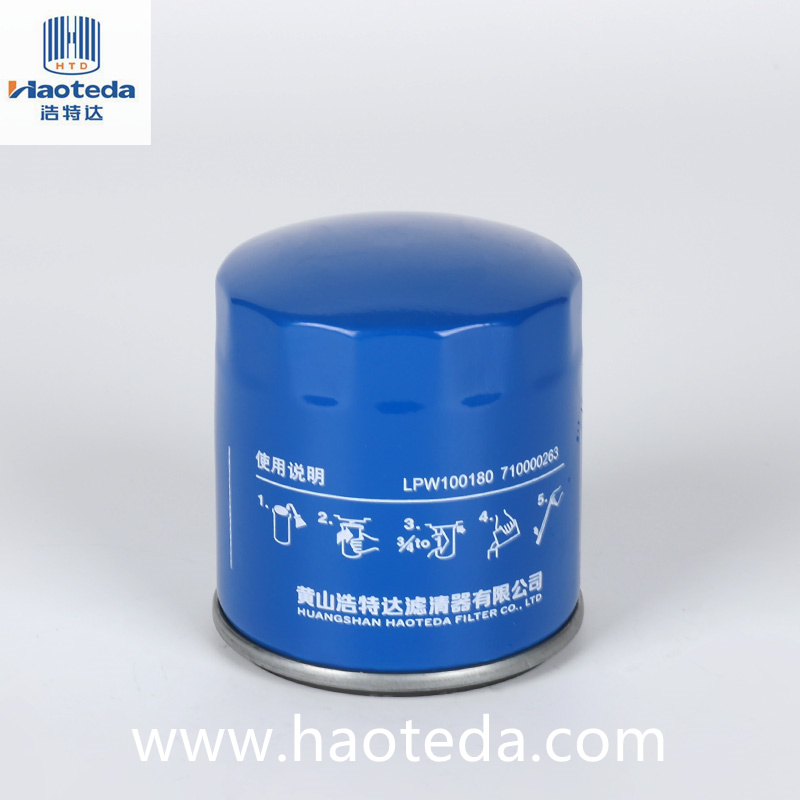

The first thing to understand about the Metal Oil Filter is that its design is intended to maximize efficiency and durability. The metal casing of the filter is more robust than traditional filters, providing superior protection against corrosion and physical damage. Additionally, it features a sealing gasket that ensures a tight fit against the engine’s mating surface. However, no matter how well-made the filter is, if the gasket isn’t properly seated, or if the filter is incorrectly tightened, oil leakage can occur, reducing filtration efficiency and causing potential damage to the engine. A small oversight can lead to larger problems down the road, so it’s essential to take the time to install it right.

One of the most common installation mistakes involves over-tightening the filter. While it might seem like a good idea to secure the Metal Oil Filter as tightly as possible, this can actually lead to damage to the filter's seal and the engine’s threading. Over-tightening can also make it much harder to remove the filter during future oil changes. A simple rule of thumb is to follow the manufacturer’s guidelines, which will typically indicate a snug fit without excessive force. Ensuring the filter is tightened just right will also help prevent leaks and maintain the proper oil pressure for optimal engine function.

Another critical factor during installation is ensuring the gasket is correctly aligned with the engine’s surface. If the gasket is misaligned or damaged during installation, it may cause oil to leak, which can lead to engine overheating or contamination. A Metal Oil Filter, designed with precision and durability in mind, should fit perfectly against the engine’s sealing surface. However, it's essential to inspect both the gasket and the surface it seals to ensure they are clean and free from debris. Even small particles can prevent the gasket from achieving a proper seal, so always double-check the installation area.

In addition to proper alignment and tightening, it's also crucial to ensure that the oil filter is installed in the right orientation. Some Metal Oil Filters are designed with a specific orientation to ensure proper oil flow and maximum filtration. Installing the filter the wrong way can lead to reduced efficiency, and in some cases, oil starvation. Always refer to the installation instructions for the correct orientation and be mindful of the specific design features of the filter you're using. Proper installation, in this case, can make a significant difference in how well the Metal Oil Filter performs over time.

Understanding the role of the bypass valve in the Metal Oil Filter is also key to successful installation. Many high-quality oil filters, including metal ones, come equipped with a bypass valve. This valve allows the oil to continue circulating in the event that the filter becomes clogged or blocked. Ensuring that the bypass valve is functioning correctly and that it hasn’t been obstructed during installation is critical to prevent engine damage. The bypass valve is a vital part of protecting your engine from contaminants, so it’s essential to verify that it is positioned and operating properly.

Finally, regular maintenance and inspections are just as important as the initial installation. Even the best-installed Metal Oil Filter can wear out over time. Regularly checking the oil filter during oil changes and replacing it at the recommended intervals will help ensure your engine continues to operate at peak efficiency. Moreover, monitoring for signs of leakage or unusual engine sounds can indicate a problem with the filter installation or performance. By staying proactive with your maintenance, you’ll help protect your engine from unnecessary damage and costly repairs.

In conclusion, proper installation of a Metal Oil Filter is essential to ensuring that your engine runs smoothly and efficiently. With the right installation practices, including correct alignment, careful tightening, and attention to the bypass valve, you can help your filter perform at its best and protect your engine for years to come. By choosing a high-quality Metal Oil Filter and installing it correctly, you're making an investment in your engine’s longevity and reliability. Don’t let a simple mistake cost you – make sure your oil filter is installed correctly and reap the benefits of a well-maintained engine.

English

English

English

English Español

Español Français

Français

+86-139-6774-0263

+86-139-6774-0263