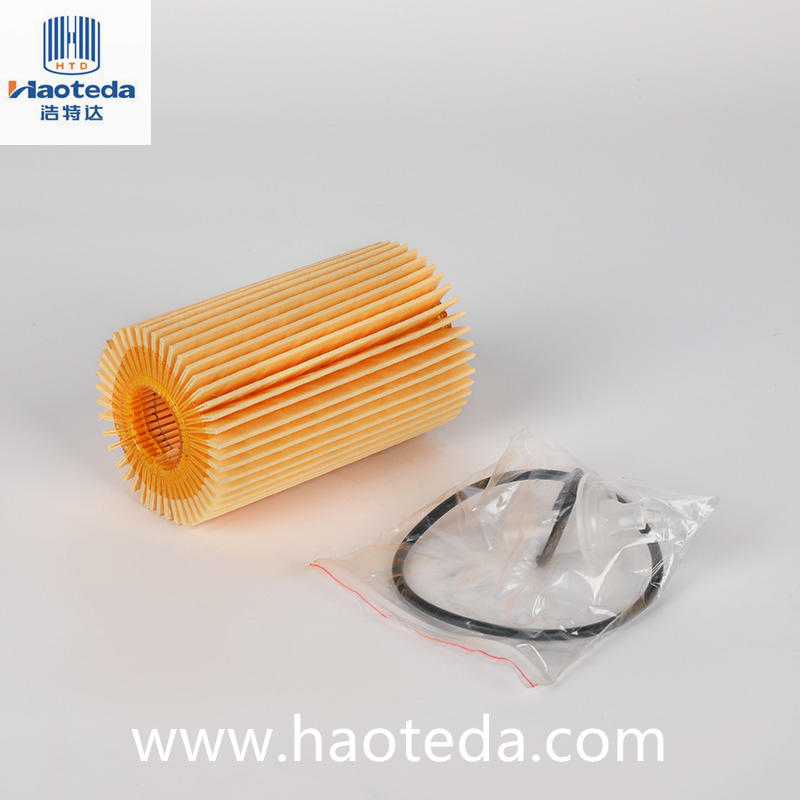

When it comes to a metal oil filter, visual inspection alone can’t tell you whether it will stand up to the rigors of long-term use in an engine running at high temperature and pressure. That's where lifecycle testing comes into play. As a manufacturer committed to reliable filtration performance, we understand that behind every high-quality oil filter is a battery of technical tests that simulate the real-world stresses these components must endure. These tests aren't just formalities—they are vital tools for predicting field performance and verifying that a product meets both customer expectations and global industry standards.

At the heart of lifecycle testing is the effort to simulate continuous flow, thermal cycling, and pressure variation in controlled environments. These tests replicate thousands of kilometers of engine operation, allowing manufacturers to assess how the filter media, bypass valve, anti-drainback valve, and sealing gasket behave over time. For instance, filters may be tested at flow rates that mirror those in high-displacement engines, and burst pressure is carefully measured to ensure structural integrity is maintained even under sudden pressure spikes. It’s these detailed simulations that ensure a filter won’t fail when it's needed most—during cold starts, heavy acceleration, or long idling cycles.

Flow resistance is another critical factor that lifecycle testing evaluates. A well-engineered metal oil filter must maintain oil flow within a defined range, ensuring that lubrication remains consistent throughout the engine's operating cycle. Over time, contaminants begin to clog the filtration media, increasing resistance. Lifecycle testing helps define the point at which flow becomes compromised—information that is essential in defining optimal service intervals. This is particularly important for commercial applications, where engine downtime directly translates to business losses.

Filtration efficiency testing also plays a central role in lifecycle assessments. Using multi-pass testing methods with standardized contaminants, manufacturers can determine what percentage of particles are captured at various micron levels. A quality metal oil filter typically needs to meet or exceed a minimum efficiency of 95% for particles above 20 microns across its intended lifespan. This level of granularity in testing helps ensure that users can trust the filter to protect engine components against wear and sludge accumulation under all operating conditions.

Thermal stability is often overlooked, but it’s essential for filters installed in high-temperature zones near exhaust manifolds or turbochargers. Over a product's lifecycle, the canister, adhesive bonds, and gasket must resist heat deformation, which could otherwise compromise sealing or cause media collapse. By cycling filters through extended periods of heating and cooling, engineers can observe how materials expand, contract, and recover—ensuring the filter remains leak-free and structurally sound throughout its service life.

These rigorous tests aren’t just scientific—they are strategic. For OEM buyers and large-scale users, a metal oil filter that’s been proven through lifecycle testing offers a measurable reduction in long-term maintenance costs and performance variability. When you’re choosing a supplier, consistency matters. Filters that pass lifecycle protocols help safeguard engines and reduce warranty claims, which is why our factory integrates these evaluations into every production batch as part of our quality commitment.

Whether you're sourcing filters for a heavy-duty fleet or a line of industrial machinery, knowing that your metal oil filter has been vetted through comprehensive lifecycle testing is not just reassuring—it’s a competitive advantage. It reflects a filter that’s built not only for today’s demands but also for tomorrow’s challenges, giving your business a durable edge in a performance-driven market.

English

English

English

English Español

Español Français

Français

+86-139-6774-0263

+86-139-6774-0263